Reducerventiler

Reducerventiler

DRV 200 / 200 G

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av deras låga friktion av de få rörliga inre delarna.

Normal storlek: DN 8 till DN 50

Inloppstryck upp till 25 bar

Utloppstryck från 0,8 upp till 8 bar

Temperaturområde -15°C till 100°C

DRV 225/226

Tryckreduceringsventiler i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av deras låga friktion av de få rörliga inre delarna.

Normal storlek: DN 8 till DN 50

Inloppstryck upp till 60 bar

Utloppstryck från 1,5 upp till 45 bar

Temperaturområde -15°C till 190°C

DRV 250

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av deras låga friktion av de få rörliga inre delarna.

Normal storlek: DN 8 upp till DN 50

Inloppstryck upp till 25 bar

Utloppstryck från 0,2 upp till 2 bar

Temperaturområde -15°C till 100°C

DRV 230 / 230 G

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av den låga friktionen hos de få rörliga interna delarna.

Normal storlek: DN 8 upp till DN 50

Inloppstryck upp till 25 bar

Utloppstryck från 0,8 upp till 8 bar

Temperaturområde -15°C till 100°C

DRV 235

Tryckreduceringsventiler i serien är kolvmanövrerade, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av deras låga friktion av de få rörliga inre delarna.

Normal storlek: DN 8 upp till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 20 bar

Temperaturområde -15°C till 190°C

DRV 302 / 303 / 308

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har inloppstryckskompensation.

Patrondesignen gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 10 bar

Temperaturområde -30°C till 190°C

DRV 302-6 / 303-6

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronensdesign gör det enkelt att byta ut de inre delarna.

Normal storlek: DN 15 till DN 50,

inloppstryck upp till 16 bar

utloppstryck från 1,5 till 6 bar

temperaturområde -15 °C till 75 °C

DRV 324 / 325

Tryckreducerare i serien är kolvstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronensdesign gör det enkelt att byta ut de inre delarna.

Normal storlek: DN 15 till DN 50,

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 350

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronensdesign gör det enkelt att byta ut de inre delarna.

Normal storlek: DN 15 till DN 50

Inloppstryck upp till 16 bar

Utloppstryck från 0,2 till 2 bar

Temperaturområde -30 °C till 190 °C

DRV 372 / 373 / 378

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronensdesign gör det enkelt att byta ut de inre delarna.

Normal storlek: DN 15 till DN 50,

Inloppstryck upp till 40 bar

Utloppstryck från 0,5 till 9 bar

Temperaturområde -30 °C till 190 °C

DRV 402 / 403 / 408

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 till DN 65

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 till 10 bar

Temperaturområde -30 °C till 190 °C

DRV 402-6 / 403-6

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp. Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 till DN 65

Inloppstryck upp till 16 bar

Utloppstryck från 1,5 upp till 6 bar

Temperaturområde -15 °C till 75 °C

DRV 424 / 425

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckkompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 65

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 450

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 65

Inloppstryck upp till 16 bar

Utloppstryck från 0,2 upp till 2 bar Temperaturområde -30 °C till 190 °C

DRV 472 / 473 / 478

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 65

Inloppstryck upp till 40 bar

Utloppstryck från 0,5 upp till 9 bar

Temperaturområde -30 °C till 190 °C

DRV 502 / 508

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 25 bar

Utloppstryck från 1,5 upp till 10 bar

Temperaturområde -30 °C till 190 °C

DRV 502-6

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 16 bar

Utloppstryck från 1,5 upp till 6 bar

Temperaturområde -15 °C till 100 °C

DRV 524 / 525

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 25 bar

Utloppstryck från 1,5 till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 550

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 16 bar

Utloppstryck från 0,2 upp till 2 bar

Temperaturområde -30 °C till 190 °C

DRV 572 / 578

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 25 bar

Utloppstryck från 0,5 upp till 9 bar

Temperaturområde -30 °C till 190 °C

DRV 602 / 608

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Alla storlekar kan fås med flänsar enligt DIN, ANSI eller JIS.

Normal storlek DN 65 upp till DN 150

Inloppstryck upp till 16/25 bar

Utloppstryck från 1,5 upp till 10 bar

Temperaturområde -30 °C till 130 °C

DRV 602-6

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Alla tätningar har ELL- och W270-godkännanden, de metalliska komponenterna överensstämmer med UBA:s positivlista.

Normal storlek DN 65 upp till DN 150

Inloppstryck upp till 16 bar

Utloppstryck från 1,5 upp till 6 bar

Temperaturområde -15 °C till 100 °C

DRV 624

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckkompensation.

Alla storlekar kan fås med flänsar enligt DIN, ANSI eller JIS.

Normal storlek DN 65 upp till DN 150

Inloppstryck upp till 25 bar

Utloppstryck från 4 upp till 12 bar

Temperaturområde -15 °C till 100 °C

DRV 672 / 678

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Alla storlekar kan fås med flänsar enligt DIN, ANSI eller JIS.

Normal storlek DN 65 upp till DN 150

Inloppstryck upp till 16/ 25 bar

Utloppstryck från 0,5 till 9 bar

Temperaturområde -30 °C till 130 °C

DRV 702 / 708

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 10 bar

Temperaturområde -30 °C till 190 °C

DRV 703/ 773

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 32

Inloppstryck upp till 16 bar

Utloppstryck från 1,5 upp till 6 bar

Temperaturområde -30 °C till 190 °C

DRV 724 / 725

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 730-D

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckkompensation.

Patronens design gör det enkelt att byta ut de inre delarna. På grund av de tätningsmaterial som används är serien idealisk för ångapplikationer.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 16 bar

Utloppstryck från 0,3 upp till 2 bar

Temperaturområde -30 °C till 200 °C

DRV 732-D / 738-D

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckkompensation.

Patronens design gör det enkelt att byta ut de inre delarna. På grund av de tätningsmaterial som används är serien idealisk för ångapplikationer.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 16 bar

Utloppstryck från 2 upp till 10 bar

Temperaturområde -30 °C till 200 °C

DRV 750

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 25 bar

Utloppstryck från 0,2 upp till 2 bar

Temperaturområde -30 °C till 190 °C

DRV 772 / 778

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 0,5 upp till 9 bar

Temperaturområde -30 °C till 190 °C

DRV 702-R / 708-R

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Storlekar DN 15 till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 till 10 bar

Temperaturområde -30 °C till 190 °C

DRV 703-R / DRV 773-R

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Storlekar DN 15 till DN 32

Inloppstryck upp till 16 bar

Utloppstryck från 0,5 till 6 bar

Temperaturområde -30 °C till 75 °C

DRV 724-R/ 725-R

Tryckreducerare i serien är kolvstyrda, fjäderbelastade Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna. Storlekar: DN 15 till DN 50, Inloppstryck upp till 16 bar Utloppstryck från 0,3 till 2 bar Temperaturområde -30 °C till 200 °C

DRV 730-D-R

Tryckreducerare i serien är kolvstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Storlekar: DN 15 till DN 50,

Inloppstryck upp till 16 bar

Utloppstryck från 0,3 till 2 bar

Temperaturområde -30 °C till 200 °C

DRV 732-D / 738-D

Tryckreducerare i serien är kolvstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna. På grund av de tätningsmaterial som används är serien idealisk för ångapplikationer.

Storlekar: DN 15 till DN 50,

Inloppstryck upp till 16 bar

Utloppstryck från 2 till 10 bar

Temperaturområde -30 °C till 200 °C

DRV 750-R

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Storlekar: DN 15 till DN 50,

Inloppstryck upp till 25 bar

Utloppstryck från 0,2 till 2 bar

Temperaturområde -30 °C till 190 °C

DRV 772-R / 778-R

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Storlekar: DN 15 till DN 50,

Inloppstryck upp till 40 bar

Utloppstryck från 0,5 till 9 bar

Temperaturområde -30 °C till 190 °C

DRV 802 / 808

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har inloppstryckskompensation.

Patrondesignen gör det enkelt att byta ut de inre delarna. Alla storlekar finns med flänsar enligt DIN, ANSI eller JIS.

Normal storlek DN 15 upp till DN 100

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 till 10 bar

Temperaturområde -30 °C upp till 190 °C

DRV 824 / 825

Tryckreduceringsventiler i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har inloppstryckskompensation.

Patrondesignen gör det enkelt att byta ut de inre delarna. Alla storlekar finns med flänsar enligt DIN, ANSI eller JIS.

Storlek DN 15 upp till DN 100

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 830-D

Tryckreduceringsventiler i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckskompensation.

Alla storlekar finns med flänsar enligt DIN, ANSI eller JIS. På grund av de tätningsmaterial som används är serien idealisk för ångapplikationer.

Storlek DN 15 upp till DN 50

Inloppstryck upp till 16 bar

Utloppstryck från 0,3 upp till 2 bar

Temperaturområde -30 °C till 200 °C

DRV 832-D / 838-D

Tryckreduceringsventiler i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckskompensation.

Alla storlekar finns med flänsar enligt DIN, ANSI eller JIS. På grund av de tätningsmaterial som används är serien idealisk för ångapplikationer.

Storlek DN 15 upp till DN 50

Inloppstryck upp till 16 bar

Utloppstryck från 2 upp till 10 bar

Temperaturområde -30 °C till 200 °C

DRV 850

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har inloppstryckskompensation.

Patrondesignen gör det enkelt att byta ut de inre delarna. Alla storlekar finns med flänsar enligt DIN, ANSI eller JIS.

Nominell storlek DN 15 upp till DN 50

Inloppstryck upp till 25 bar

Utloppstryck från 0,2 upp till 2 bar

Temperaturområde -30 °C till 190 °C

DRV 872 / 878

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har inloppstryckskompensation.

Patrondesignen gör det enkelt att byta ut de inre delarna. Alla storlekar finns med flänsar enligt DIN, ANSI eller JIS.

Nominell storlek DN 15 upp till DN 100

Inloppstryck upp till 40 bar

Utloppstryck från 0,5 upp till 9 bar

Temperaturområde -30 °C till 190 °C

RP45 (SV) EN

ADCA RP45-seriens tryckreducerande ventiler är ensitsiga, bälgförseglade styrenheter som

fungerar utan extra energi. Konstruerad för användning med ånga, tryckluft och andra gaser

som är kompatibla med konstruktionen. Dessa ventiler är särskilt lämpliga för att minska

ångtrycket i alla energi- och processystem där trycket måste hållas under kontroll.

MATERIAL: SG Järn, kolstål eller rostfritt stål

STORLEKAR: DN 15 - 150

ANSLUTNINGAR: Flänsad EN PN 16 eller PN 40

MAX UPPSTRÖMS TRYCK: Upp till 25 bar

DRIFTSTEMPERATUR: Upp till 250 ºC

REGLERANDE INTERVALL: 0,15 till 18 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

4,8 till 204 Kvs (m3/h)

RP45 (ASME)

ADCA RP45-seriens tryckreducerande ventiler är ensitsiga, bälgförseglade styrenheter som

fungerar utan extra energi. Konstruerad för användning med ånga, tryckluft och andra gaser

som är kompatibla med konstruktionen. Dessa ventiler är särskilt lämpliga för att minska

ångtrycket i alla energi- och processystem där trycket måste hållas under kontroll.

MATERIAL: Kolstål

STORLEKAR: 1/2'' till 6''

ANSLUTNINGAR: Flänsad ASME B16.5 klass 150 eller 300

MAX UPPSTRÖMS TRYCK: Upp till 25 bar

DRIFTSTEMPERATUR: Upp till 250 ºC

REGLERANDE INTERVALL: 0,15 till 18 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

4,8 till 204 KVS

RPW45B

ADCA RPW45B-serien tryckreducerande ventiler är ensitsiga, membranavkännande proportionella

styrenheter som fungerar utan hjälpenergi. Konstruerad för användning med vatten, tryckluft

och andra vätskor och gaser som är kompatibla med konstruktionen.

MATERIAL: SG Järn, kolstål eller rostfritt stål

STORLEKAR: DN 50 till DN 100

ANSLUTNINGAR: Flänsad EN 1092-1 PN 16 eller PN 40

MAX UPPSTRÖMS TRYCK: Upp till 40 bar

DRIFTSTEMPERATUR: 130 ºC

REGLERANDE INTERVALL: 0,2 till 18 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

26,5 till 129,5 KVS (m3/h)

RP45TW

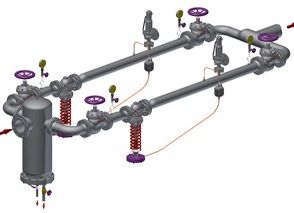

ADCA RP45TW-seriens tryckreducerande station består av två standard RP45-ventiler installerade parallellt.

Detta system rekommenderas särskilt för installationer där en enda ventil inte kan nå den maximala

erforderliga flödeshastigheten eller när förbrukningsvariationen är betydande, eftersom det är klokt

att installera två mindre ventiler istället för en enda för att undvika överdimensionering.

Detta system rekommenderas också när det är viktigt att ångtillförseln inte avbryts.

PS46-seriens

Tryckbärande ventiler är ensitsiga, membran- eller kolvavkännande bälgförseglade styrenheter som fungerar utan extra energi. Dessa ventiler är konstruerade för användning med ånga, tryckluft och andra gaser som är kompatibla med konstruktionen. Dessa ventiler är särskilt lämpliga för att upprätthålla ångtrycket i alla energi- och processystem där minimala uppströmstryck måste hållas under kontroll. MATERIAL: Kolstål STORLEKAR: DN 15 till DN 100 ANSLUTNINGAR: Flänsad EN 1092-1 PN 16 eller PN 40 MAX UPPSTRÖMS TRYCK: Upp till 18 bar DRIFTSTEMPERATUR: Upp till 250 ºC FLÖDESHASTIGHETSKOEFFICIENTER: 4,8 till 129,5 KVSPSW46B

Serie tryckventiler är ensitsiga, membran- eller kolvavkännande proportionella regulatorer som fungerar utan hjälpenergi. Konstruerad för användning med vatten, tryckluft och andra vätskor och gaser som är kompatibla med konstruktionen. MATERIAL: Kolstål STORLEKAR: DN 50 till DN 100 ANSLUTNINGAR: Flänsad EN 1092-1 PN 16 eller PN 40 MAX UPPSTRÖMS TRYCK: Upp till 18 bar DRIFTSTEMPERATUR: 130 ºC FLÖDESHASTIGHETSKOEFFICIENTER: 26,5 till 129,5 KVS

PS47

ADCA PS47 pilotstyrda tryckhållningsventiler är konstruerade för användning med ånga, tryckluft,

kväve och andra gaser som är kompatibla med byggmaterialen. PS47 känner exakt av uppströmstrycket

och verkar för att exakt styra det till ett minimum eller sprida övertrycket.

MATERIAL: Kolstål eller rostfritt stål

STORLEKAR: 1/2"-l 2"– DN 15- 50

ANSLUTNINGAR:

Flänsad EN PN 40

Flänsad ASME klass 150 eller 300

hongängad ISO 7 RP eller NPT-sockelsvets

(SW) ASME B16.11

MAX UPPSTRÖMS TRYCK: 17 bar

DRIFTSTEMPERATUR: 250 ºC

REGLERANDE INTERVALL:

0,07 till 17 bar

PRV47

ADCA PRV47 pilotdrivna tryckreducerande ventiler är konstruerade för användning med ånga,

tryckluft, kväve och andra gaser som är kompatibla med byggmaterialen. PRV47 kan installeras

i tryckreducerande stationer i alla branscher och ger känslig och exakt kontroll även när

inloppstrycksfluktuationer eller flödesvariationer uppstår.

MATERIAL: Kolstål eller rostfritt stål

STORLEKAR: 1/2" till 2" – DN 15 till DN 50

ANSLUTNINGAR:

Gängad ISO 7 RP eller NPT-flänsad

EN PN 40

flänsad ASME klass 150 eller 300

sockelsvets (SW) ASME B16.11

MAX UPPSTRÖMS TRYCK: 28 bar

DRIFTSTEMPERATUR:250 ºC

REGLERANDE INTERVALL:

0,07 till 17 bar

Prv57

ADCA PRV57 pilotdrivna tryckreducerande ventiler är konstruerade för användning med ånga, tryckluft, kväve och andra gaser som är kompatibla med byggmaterialen. PRV57 kan installeras i tryckreducerande stationer i alla branscher och ger känslig och exakt kontroll även när inloppstrycksfluktuationer eller relevanta flödesvariationer uppstår. MATERIAL: Kolstål eller rostfritt stål STORLEKAR: DN 15 - 100 ANSLUTNINGAR: Flänsad EN 1092-1 PN 16 eller PN 40 MAX UPPSTRÖMS TRYCK: 28 bar DRIFTSTEMPERATUR: 250 ºC REGLERANDE INTERVALL: 0,07 till 17 bar

PS4

ADCA PS4 är en serie direktverkande, fjäderbelastade membranavkännings-, tryckbärande ventiler konstruerade för användning med tryckluft, vatten och andra gaser eller vätskor som är kompatibla med konstruktionen. Ventilens huvudsyfte är att hålla uppströmstrycket under kontroll i applikationer där små belastningar är inblandade. Dessa ventiler rekommenderas också specifikt för att fungera som pilotventiler i kombination med andra tryckregulatorer.

MATERIAL: Kolstål eller rostfritt stål

STORLEKAR: 1/2"- 1"

ANSLUTNINGAR: Hongängad ISO 7 RP eller NPT

MAX UPPSTRÖMS TRYCK: 15 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 0,35 till 17 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

3,6 eller 3,7 KVS

P7

ADCA P7-serien direktverkande, fjäderbelastade membranavkännande tryckreducerande ventiler är

konstruerade för användning med ånga, tryckluft och andra gaser som är kompatibla med

konstruktionsmaterialen. De är lämpliga för tryckreducerande stationer där mycket små

belastningar är inblandade. De rekommenderas också specifikt att fungera som pilotventiler

i kombination med andra tryckregulatorer.

MATERIAL: Rostfritt stål

STORLEKAR: 1/4" eller 3/8"

ANSLUTNINGAR: Gängad ISO 7 RP eller NPT

MAX UPPSTRÖMS TRYCK: 25 bar (ånga)31 bar (gaser)

DESIGNTEMPERATUR: 300 ºC

REGLERANDE INTERVALL: 0,35 till 17 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

1 eller 1,1 KVS (m3/h)

PS7

ADCA PS7-seriens direktverkande, fjäderbelastade membranavkännande tryckhållningsventiler är konstruerade för användning med ånga, tryckluft och andra gaser som är kompatibla med konstruktionsmaterialen. De är lämpliga för tryckbärande applikationer där mycket små belastningar är inblandade. De rekommenderas också specifikt att fungera som pilotventiler i kombination med andra tryckregulatorer.

MATERIAL: Kolstål eller rostfritt stål

STORLEKAR: 1/4" och 3/8"

ANSLUTNINGAR: Hongängad ISO 7 RP eller NPT

MAX UPPSTRÖMS TRYCK: 17 bar

DESIGNTEMPERATUR: 300 ºC

REGLERANDE INTERVALL: 0,35 till 17 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

0,8 KVS

P20D

ADCA P20D är en serie direktverkande, fjäderbelastade, membranavkännande och balanserade pluggtrycksreducerande

ventiler. Dessa regulatorer är konstruerade för användning med tryckluft, vatten och andra gaser och vätskor

som är kompatibla med byggmaterial och ventildesign. De är lämpliga för tryckreducerande applikationer vid

användningsstället i tvätt- och färgningsmaskiner, livsmedelsindustrier, autoklaver etc.

MATERIAL: Rostfritt stål

STORLEKAR: 1/4" till 1/2" – DN 15

ANSLUTNINGAR:

Hongängad ISO 7 RP, ISO 228 eller NPT

Flänsad EN 1092-1 PN 40

Flänsad ASME B16.5 Klass 150 eller 300

MAX UPPSTRÖMS TRYCK: 50 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 0,2 till 15 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

1,2 till 1,8 kV

P20DS

ADCA P20DS är en serie direktverkande, fjäderbelastade, membranavkännande balanserade pluggtrycksreducerande

ventiler. Dessa regulatorer är särskilt lämpliga för allmänna applikationer där lågt flöde och höga

temperaturer är inblandade och har utformats speciellt för användning med ånga.

MATERIAL: Rostfritt stål

STORLEKAR: 1/4" till 1/2" – DN 15

ANSLUTNINGAR:

Hongängad ISO 7 Rp, ISO 228 eller NPT

Flänsad EN 1092-1 PN 40

Flänsad ASME B16.5 Klass 150 eller 300

MAX UPPSTRÖMS TRYCK: 14 bar

DESIGNTEMPERATUR: 200 ºC

REGLERANDE INTERVALL: 0,2 till 8 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

1,2 till 1,8 kV

P20P

ADCA P20P är en serie direktverkande, fjäderbelastade, kolvavkännande tryckreducerande ventiler.

Dessa regulatorer är konstruerade för användning med kväve, tryckluft, vatten och andra gaser och

vätskor som är kompatibla med konstruktionsmaterialen. De är lämpliga för allmänna tryckreducerande

applikationer som instrumentsystem och industriell utrustning där små belastningar och höga tryck är inblandade.

MATERIAL: Rostfritt stål

STORLEKAR: 1/4"

ANSLUTNINGAR:

Innergängad ISO 7 RP, ISO 228 eller NPT

MAX UPPSTRÖMS TRYCK: 220 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 0,2 till 200 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

0,043 till 0,62 KVS

Prv25

ADCA PRV25 är en serie direktverkande tryckreducerande ventiler konstruerade för användning på ånga,

tryckluft, vatten och andra gaser och vätskor. Dessa regulatorer är lämpliga för att minska

ångtrycket vid användning på tvättmaskiner, färgning, livsmedelsindustri, autoklaver etc.

MATERIAL: Kolstål eller rostfritt stål

STORLEKAR: 1/2"- 1" – DN 15- 25

ANSLUTNINGAR: Gängad ISO 7 RP flänsad EN PN 25

flänsad ASME klass 150 eller 300

MAX UPPSTRÖMS TRYCK: Upp till 17 bar

DESIGNTEMPERATUR: Upp till 210 ºC

REGLERANDE INTERVALL: 0,35 till 8,6 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

1,7 till 3,1 kV

PS30SS

ADCA PS30SS är en serie direktverkande, fjäderbelastade membranavkännande tryckhållande ventiler. Dessa regulatorer är konstruerade för användning med tryckluft, vatten och andra gaser och vätskor som är kompatibla med byggmaterial och ventildesign. De är lämpliga för tryckbärande applikationer vid användningsstället i tvätt- och färgningsmaskiner, livsmedelsindustrier, autoklaver etc.

MATERIAL: Rostfritt stål

STORLEKAR: 1/2"- 1" – DN 15- 25

ANSLUTNINGAR:

Gängad ISO 7 RP eller NPT-flänsad EN PN 40

flänsad ASME-klass 150 eller 300

MAX UPPSTRÖMS TRYCK: 15 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 0,2 till 15 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

Upp till 6,5 m3/h

ADCA PRV30SS

Är en serie direktverkande, fjäderbelastade, membranavkännande och balanserade pluggtrycksreducerande ventiler. Dessa regulatorer är konstruerade för användning med tryckluft, vatten och andra gaser och vätskor som är kompatibla med byggmaterial och ventildesign. De är lämpliga för tryckreducerande applikationer vid användningsstället i tvätt- och färgningsmaskiner, livsmedelsindustrier, sterilisationer etc. MATERIAL: Rostfritt stål STORLEKAR: 1/2" till 1" – DN 15 - 25 ANSLUTNINGAR: Gängad ISO 7 RP eller NPT-flänsad EN 1092-1 PN 40 flänsad ASME B16.5 klass 150 eller 300 MAX UPPSTRÖMS TRYCK: 50 bar DESIGNTEMPERATUR: 80 ºC REGLERANDE INTERVALL: 0,2 till 15 bar FLÖDESHASTIGHETSKOEFFICIENTER: Upp till 6,5 m3/h

Prv30

ADCA PRV30SS är en serie direktverkande, fjäderbelastade, membranavkännande och balanserade pluggtrycksreducerande

ventiler. Dessa regulatorer är konstruerade för användning med tryckluft, vatten och andra gaser och vätskor

som är kompatibla med byggmaterial och ventildesign. De är lämpliga för tryckreducerande applikationer

vid användningsstället i tvätt- och färgningsmaskiner, livsmedelsindustrier, Autoklaver etc.

MATERIAL: Rostfritt stål

STORLEKAR: 1"- 2" – DN 25- 50

ANSLUTNINGAR:

Gängad ISO 7 RP eller NPT-flänsad

EN 1092-1 PN 40

Flänsad ASME B16.5 klass 150, 300 eller 600

MAX UPPSTRÖMS TRYCK: 50 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 0,2 till 15 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

Upp till 13,7 m3/h

Prv31

ADCA PRV31SS är en serie direktverkande, fjäderbelastade, kolvavkännande och balanserade

pluggtrycksreducerande ventiler. Dessa regulatorer är konstruerade för användning med tryckluft,

vatten och andra gaser och vätskor som är kompatibla med byggmaterial och ventildesign.

De är lämpliga för tryckreducerande applikationer vid användningsstället i tvätt och

färgningsmaskiner, livsmedelsindustrier, autoklaver etc.

MATERIAL: Rostfritt stål

STORLEKAR: 1/2"- 1" – DN 15- 25

ANSLUTNINGAR:

gängad ISO 7 RP eller NPT-flänsad

EN 1092-1 PN 40

flänsad ASME B16.5 klass 150 eller 300

MAX UPPSTRÖMS TRYCK: 50 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 3 till 50 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

Upp till 7,5 m3/h

Prv31

ADCA PRV31SS är en serie direktverkande, fjäderbelastade, kolvavkännande och balanserade pluggtrycksreducerande

ventiler. Dessa regulatorer är konstruerade för användning med tryckluft, vatten och andra gaser och

vätskor som är kompatibla med byggmaterial och ventildesign. De är lämpliga för tryckreducerande applikationer

vid användningsstället i tvätt- och färgningsmaskiner, livsmedelsindustrier, autoklaver etc.

MATERIAL: Rostfritt stål

STORLEKAR: 1"- 2"– DN 25- 50

ANSLUTNINGAR:

Gängad ISO 7 RP eller NPT-flänsad

EN 1092-1 PN 40

flänsad ASME B16.5 klass 150 eller 300

MAX UPPSTRÖMS TRYCK: 50 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 3 till 50 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

Upp till 15,4 m3/h

PS31SS

ADCA PS31SS är en serie direktverkande, fjäderbelastade, kolvavkännande tryckhållande ventiler. Dessa regulatorer är konstruerade för användning med tryckluft, vatten och andra gaser och vätskor som är kompatibla med byggmaterialen och designen. De är lämpliga för tryckbärande applikationer vid användningsstället i tvätt- och färgningsmaskiner, livsmedelsindustrier, autoklaver etc.

MATERIAL: Rostfritt stål

STORLEKAR: 1/2"- 1"– DN 15- 25

ANSLUTNINGAR:

Gängad ISO 7 RP eller NPT-flänsad EN PN 40

flänsad ASME-klass 150 eller 300

MAX UPPSTRÖMS TRYCK: 50 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 3 till 50 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

Upp till 7,5 m3/h

Prv41

ADCA PRV41SS är en serie direktverkande, fjäderbelastade, kolvavkännande tryckreducerande ventiler.

Dessa regulatorer är konstruerade för användning med kväve, tryckluft, vatten och andra gaser och

vätskor som är kompatibla med konstruktionsmaterialen. De är lämpliga för allmänna tryckreducerande

applikationer som instrumentsystem och industriell utrustning där små belastningar och höga tryck är inblandade.

MATERIAL: Rostfritt stål

STORLEKAR: 1/4"- 3/4"– DN 15- 20

ANSLUTNINGAR:

Hongängad ISO 7 RP, ISO 228 eller NPT

Flänsad EN PN 40 till PN 250

Flänsad ASME klass 150, 300 eller 600

MAX UPPSTRÖMS TRYCK: 220 bar

DESIGNTEMPERATUR: 80 ºC

REGLERANDE INTERVALL: 3 till 200 bar

FLÖDESHASTIGHETSKOEFFICIENTER:

Upp till 0,9 Kvs

BKVi2

Tankfiltventiler används ofta i tanklagringssystem för att förhindra och skydda mot explosioner (undvika att brandfarliga vätskor ventileras från ett kärl), för att kontrollera produktförorening mot yttre luft som kan fylla ångutrymmet, för att minska avdunstningsförluster (följaktligen produktionsförluster), för att minska inre korrosion (orsakad av luft och fukt) och för att förhindra vakuumtillstånd. Filtningsprocessen består av att täcka det lagrade mediet, vanligtvis en vätska, med en gas (normalt N2).

MATERIAL: Rostfritt stål

STORLEKAR: DN 15- DN 25

ANSLUTNINGAR: Flänsad EN PN 16

MAX. ARBETSTRYCK: 6 bar

DESIGNTEMPERATUR: 130 ºC

REGLERANDE INTERVALL:

5 till 4000 mbar

BKRi2

Tankfiltventiler används ofta i tanklagringssystem för att förhindra och skydda mot explosioner (undvika att brandfarliga vätskor ventileras från ett kärl), för att kontrollera produktförorening mot yttre luft som kan fylla ångutrymmet, för att minska avdunstningsförluster (följaktligen produktionsförluster), för att minska inre korrosion (orsakad av luft och fukt) och för att förhindra vakuumtillstånd. Filtningsprocessen består av att täcka det lagrade mediet, vanligtvis en vätska, med en gas (normalt N2).

MATERIAL: Rostfritt stål

STORLEKAR: DN 15 DN 25

ANSLUTNINGAR: Flänsad EN PN 16

MAX UPPSTRÖMS TRYCK: 12 bar

DESIGNTEMPERATUR: 130 ºC

REGLERANDE INTERVALL:

5 till 4000 mbar

Mods. 614 SV ASME/ANSI

Tryckreducerande ventiler för ånga och gaser.

Lämplig för användning i: strykmaskiner, tvättstugor och kemtvättar, matlagningsbehållare,

textilmaskiner, torkcylindrar, autoklaver, ångugnar, destillerier, värmeväxlare,

livsmedelsindustrin, kemiska laboratorier etc.

Anslutning: Fläns x Fläns

DN: 25 - 50

Material: Carbon steel. PN 16

Säte: Metal

Beroende på modell

-10 to +120ºC, 1,40 to 16,00 bar, Ånga/Gas

AB

Tryckreduceringsventilerna som är lämplig för användning på tryckluft, gas, vatten och olja. Dessa ventiler används i en mängd olika

tillämpningar i hela industrin, där de är enastående noggrannhet och tillförlitlighet har bevisats. AB är också en WRAS-godkänd produkt.

Ventiler finns i storlek ½” - 2” i rostfritt stål eller S. G. Järn. Ändarna är Inv. gängad. Inloppstryck på upp till 27,60 Bar.

Reducerade tryckområden på 0,70 – 8,30 Bar Alla ventiler levereras med nitrilskiva och membran för luft, gaser, oljor etc. som standard.

Ventiler för dricksvattenservice levereras med neoprenskiva och diafragma.

Typ B2

Pilotopererade ångtrycksreducerande / reglerventil finns i storlekarna DN 15 - 150 med ett maximalt inloppstryck på 28 bar och ett reducerat tryckområde på 0,35 bar till 17,50 bar. Ventilen är lämplig för ång-, luft- och gasapplikationer.

Flänsar I enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220.

Gängade anslutningar i NPT eller BSP.

Material: SG Järn, kolstål eller rostfritt stål

Maximalt inloppstryck:

28.00 Bar (15NB till 25NB)

25.00 Bar (32NB till 50NB)

21.00 Bar (65NB till 150NB)

Minskat tryckområde 0.35 Bar till 17.50 Bar

Medium: Ång-, luft- och gasapplikationer

Typ C3

Självverkande tryckreducerande/reglerventil finns i storlekarna DN 15 - 100 med ett maximalt inloppstryck på 21 bar och ett reducerat tryckområde på 0,35 bar till 8,30 bar. Ventilen är lämplig för ång-, luft-, gas- och vätskeapplikationer.

Storlekar DN 15- 100

Flänsar i enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220

Inv. Gängad anslutning i NPT eller BSP

Material gunmetall, rostfritt stål, aluminiumbrons och duplex rostfritt stål

Maximalt inloppstryck: 17.50 Bar (ånga), 21.00 Bar (gas & vätska)

Minskat tryckområde 0.35 Bar till 8.30 Bar

Medium: Ång-, luft-, gas- och vätsketillämpningar

C3-L

Lågtryckstankens filttrycksreducerande/reglerventil finns i storlekarna DN 15- 100 med ett maximalt inloppstryck på 10 bar och ett reducerat tryckområde på 10 till 350 mbar. Ventilen är lämplig på luft- och gasapplikationer.

Storlekar DN 15- 100

Flänsar: I enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220

Inv. gängade anslutningar i NPT eller BSP

Material: Gunmetall, rostfritt stål, aluminiumbrons och duplex rostfritt stål

Maximalt inloppstryck 10.00 Bar, 21.00 Bar (gas & vätska)

Minskat tryckområde10 till 350 mbar

C4

Självverkande högtrycksreducerande/reglerventil finns i storlekarna DN 6- 100 med ett maximalt inloppstryck på 345 bar och ett reducerat tryckområde på 1,00 bar till 70,00 bar. Ventilen är lämplig för ång-, luft-, gas- och vätskeapplikationer.

Storlekar DN 6- 100, 1/8"- 11/4" gängade

Flänsar i enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220

Gängade anslutningar i NPT eller BSP

Avsluta anslutningar i Stumsvets och sockelsvetsändar finns

Material, Kolstål, rostfritt stål, gunmetall, duplex rostfritt stål

Maximalt inloppstryck 345.00 Bar (6NB till 25NB), 138.00 Bar (32NB till 100 NB)

Minskat tryckområde 1.00 Bar till 7.00 Bar

Medium Ång-, luft-, gas- och vätsketillämpningar

C6

Självverkande tryckreducerande/reglerventil finns i storlekarna DN 15- 32 med ett maximalt inloppstryck på 21 bar och ett reducerat tryckområde på 0,35 bar till 8,30 bar. Ventilen är lämplig för ång-, luft-, gas- och vätskeapplikationer.

Storlekar DN 15- 32

Flänsar i enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220

Gängade anslutningar i NPT eller BSP

Material: Gunmetall, rostfritt stål, aluminiumbrons och duplex rostfritt stål

Maximalt inloppstryck, 17.50 Bar (ånga), 21.00 Bar (gas & vätska)

Minskat tryckområde 0.35 Bar till 8.30 Bar

Medium: Ång-, luft-, gas- och vätsketillämpningar

C7

Självverkande tryckreducerande / reglerventil finns i storlekarna DN 15- 50 med ett maximalt inloppstryck på 42 bar och ett reducerat tryckområde på 0,35 bar till 10,00 bar. Ventilen är lämplig för ång-, luft-, gas- och vätskeapplikationer.

Storlekar DN 15- 50

Flänsar i enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220

Gängade anslutningar i NPT eller BSP

Material: Kolstål

Maximalt inloppstryck: 42.00 Bar

Minskat tryckområde 0,35 Bar till 10 Bar

Media: Ång-, luft-, gas- och vätsketillämpningar

C8

Självverkande tryckreducerande / reglerventil finns i storlekarna DN 15- 50 med ett maximalt inloppstryck på 42 bar och ett reducerat tryckområde på 0,35 bar till 10,00 bar. Ventilen är lämplig för ång-, luft-, gas- och vätskeapplikationer.

Storlekar DN 15- 50

Flänsar i enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220

Gängade anslutningar i NPT eller BSP

Material: Rostfritt stål

Maximalt inloppstryck 42.00 Bar

Minskat tryckområde 0,35 Bar till 10 Bar

Media. Ång-, luft-, gas- och vätsketillämpningar

C9

Självverkande tryckreducerande/reglerventil finns i storlekarna DN 6- 100 med ett maximalt inloppstryck på 83 bar och ett reducerat tryckområde på 1,50 bar till 21 bar. Ventilen är lämplig för ång-, luft-, gas- och vätskeapplikationer.

Storlekar DN 6- 100, 1/8"- 2" Gängad

Flänsar i enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220

Gängade anslutningar i NPT eller BSP

Avslutande anslutningar i Stumsvets och sockelsvetsändar finns

Material: Kolstål, rostfritt stål, gunmetall, duplex rostfritt stål

Maximalt inloppstryck 83.00 Bar 25NB)

Minskat tryckområde 1.50 Bar till 21.00 Bar

Media: Ång-, luft-, gas- och vätsketillämpningar

D

Balanserad inloppsventil för högkapacitetstryckreducering/reglering finns i storlekarna DN 15- 200 med ett maximalt inloppstryck på 20 bar och ett reducerat tryckområde på 0,35 bar till 13,80 bar. Ventilen är lämplig vid vätskeapplikationer.

Storlekar DN 15- 200, ½"- 2" Gängade

Flänsar i enlighet med ASME B16.5, DIN EN 1092-1 eller JIS 2220

Gängade anslutningar i NPT eller BSP

Material Gunmetall, SG Järn, Aluminium Brons och Rostfritt Stål

Maximalt inloppstryck 20.00 Bar

(Högtrycksdesign för inlopp upp till 45,00 Bar finns på begäran)

Minskat tryckområde 0,35 Bar till 13,80 Bar

Media: Flytande applikationer

Tryckreducerande ventil T6, för ånga

Funktionen hos tryckreducerande ventiler (tryckreglerande ventiler) är att minska ångans varierande eller konstanta uppströmstryck (inloppstryck) till ett konstant reducerat tryck (utloppstryck, mottryck) som är beroende av uppströmstrycket.

Tryckreduktionen sker genom att strypa det fria tvärsnittet mellan sätet och konen. Varje tryckförändring på trycksidan nedströms omvandlas omedelbart till en lyftrörelse av ventilkonen.

Vid nollförbrukning, det vill säga när förbrukningen på nedströms trycksidan är noll, stänger ventilen inte tätt.

Det finns inget behov av ytterligare tillbehör som en vattentätningskruka. Det är möjligt att installera ventilen snabbt och enkelt.

De används främst i industrianläggningar, anläggningsteknik och processteknik.

Tryckreducerande ventiler kan levereras med flänsar, svetsändar eller gängade anslutningar.

DN15 till DN200 (1/2"- 8")

PN16 till PN40

utloppstryck: 1–40 bar

för ånga

SV-JS1030, 1.0619, 1.7357, 1.4408

Tryckreducerande ventil – modell T7, för ånga

Funktionen hos tryckreducerande ventiler (tryckreglerande ventiler) är att minska ångans varierande eller konstanta uppströmstryck (inloppstryck) till ett konstant reducerat tryck (utloppstryck, mottryck) som är oberoende av uppströmstrycket.

Tryckminskningen sker genom att strypa det fria tvärsnittet mellan sätet och konen. Via en pulsledning, som redan är installerad på ventilen, trycker det reducerade trycket på en styrkolv. Som ett resultat omvandlas varje tryckförändring på trycksidan nedströms omedelbart till en lyftrörelse av ventilkonen.

Ventilen är väl lämpad för intermittent konsumtion. Vid nollförbrukning, det vill säga när förbrukningen på nedströms trycksidan är noll, stängs ventilen säkert genom lågtrycksökning.

Det finns inget behov av ytterligare tillbehör som en vattentätningskruka. Det är möjligt att installera ventilen snabbt och enkelt.

De används främst i industrianläggningar, anläggningsteknik och processteknik.

Tryckreducerande ventiler kan levereras med flänsar, svetsändar eller gängade anslutningar.

DN 15- DN 200 (1/2" bis 8")

PN 16- PN 40

utloppstryck: 0,5–20 bar

för ånga

SV-JS1030, 1.0619, 1.7357, 1.4408

Tryckreducerande ventil – modell T9, för vätskor och gaser

Funktionen hos tryckreducerande ventiler (tryckreglerande ventiler) är att minska ett varierande eller konstant uppströmstryck (inloppstryck) i mediet till ett konstant reducerat tryck (utloppstryck, mottryck) som är oberoende av uppströmstrycket.

Tryckminskningen sker genom att strypa det fria tvärsnittet mellan sätet och konen. Via en pulsledning, som redan är installerad på ventilen, trycker det reducerade trycket på en styrkolv. Som ett resultat omvandlas varje tryckförändring på trycksidan nedströms omedelbart till en lyftrörelse av ventilkonen.

Ventilen är väl lämpad för intermittent konsumtion. Vid nollförbrukning, det vill säga när förbrukningen på nedströms trycksidan är noll, stängs ventilen säkert genom lågtrycksökning.

Den tryckreducerande ventilen T9 är lämplig för inkompressibla medier, t.ex. tryckluft, naturgas, kväve, samt för inkompressibla medier, t.ex. vatten, olja, bränslen, gasol (propan, butan) etc.

De används främst i industrianläggningar, anläggningsteknik och processteknik.

Tryckreducerande ventiler kan levereras med flänsar, svetsändar eller gängade anslutningar.

DN 15- DN 200 (1/2" bis 8")

PN 16- PN 40

utloppstryck: 0,5–20 bar

för vätskor och gaser

EN-JS1030, 1.0619, 1.4408, 1.4410, CC480K, CC333G

Överflödesventil – Modell T27, för vätskor och gas

Funktionen hos överflödesventiler (avlastningsventiler, tryckhållande ventiler) är, att utflödet av mediet vid ett inställt tryck, där ett befintligt mottryck eller vakuum inte har någon effekt på uppsättningen över tryck (kvarhållande tryck). Ovanstående punkter är karakteristiska för en uppströms tryckregulator, jämfört med en normal säkerhetsventil. Säkerhetsventilen är endast en anordning för att förhindra att ett specifikt tryck överskrids (inställt tryck).

Överflödesventilen T27 är en ensitsventil och är särskilt lämplig för inkompressibla medier, till exempel vatten, olja (smörjolja, eldningsolja, HFO, LFO, MGO) etc. Ventilerna är helt avlastade så att mottrycket inte har någon effekt på det inställda (överflödes) trycket, endast flödesmängden ändras beroende på tryckskillnaden.

De används främst i pumpkretsar för att hålla ett visst tryck konstant.

Tätningen mellan styrhylsan och konen sker med en O-ring.

Överflödesventiler (avlastningsventiler) kan levereras med flänsar, svetsändar eller gängade anslutningar.

D15- DN 200 (1/2"- 8")

PN 16- PN 40

utloppstryck: 0,5–40 bar

för vätskor och gaser

EN-JS1030, 1.0619, 1.4408, 1.4410, CC480K, CC333G

Spillventil T27F, för vätskor, gas och ånga

Funktionen hos överflödesventiler (avlastningsventiler, tryckhållande ventiler) är, att utflödet av mediet vid ett inställt tryck, där ett befintligt mottryck eller vakuum inte har någon effekt på uppsättningen över tryck (kvarhållande tryck). Ovanstående punkter är karakteristiska för en uppströms tryckregulator, jämfört med en normal säkerhetsventil. Säkerhetsventilen är endast en anordning för att förhindra att ett specifikt tryck överskrids (inställt tryck).

Överflödesventilen T27 är en ensitsventil och är särskilt lämplig för inkompressibla medier, till exempel vatten, olja (smörjolja, eldningsolja, HFO, LFO, MGO) etc. Ventilerna är helt avlastade så att mottrycket inte har någon effekt på det inställda (överflödes) trycket, endast flödesmängden ändras beroende på tryckskillnaden.

De används främst i pumpkretsar för att hålla ett visst tryck konstant.

Tätningen mellan styrhylsan och konen sker med en bälg i rostfritt stål.

Överflödesventiler (avlastningsventiler) kan levereras med flänsar, svetsändar eller gängade anslutningar.

DN 15- DN 200 (1/2"- 8")

PN 16- PN 40

utloppstryck: 0,5–40 bar

med rostfritt stål bälg 1.4571

för vätskor, gaser och ånga

EN-JS1030, 1.0619, 1.4408, 1.4410, CC480K, CC333G

Tryckreducerande ventil T65, för vätskor och gaser

Funktionen hos tryckreducerande ventiler (tryckreglerande ventiler) är att minska ett varierande eller konstant uppströmstryck (inloppstryck) i mediet till ett konstant reducerat tryck (utloppstryck, mottryck) som är beroende av uppströmstrycket.

Tryckreduktionen sker genom att strypa det fria tvärsnittet mellan sätet och konen. Varje tryckförändring på trycksidan nedströms omvandlas omedelbart till en lyftrörelse av ventilkonen.

Vid nollförbrukning, det vill säga när förbrukningen på nedströms trycksidan är noll, stänger ventilen inte tätt.

Den tryckreducerande ventilen T65 är lämplig för inkompressibla medier, t.ex. tryckluft, naturgas, kväve, samt för inkompressibla medier, t.ex. vatten, olja, bränslen, gasol (propan, butan) etc.

De används främst i industrianläggningar, anläggningsteknik och processteknik.

Tryckreducerande ventiler kan levereras med flänsar, svetsändar eller gängade anslutningar.

DN 15- DN 200 (1/2"- 8")

PN 1- PN 40

utloppstryck: 1– 40 Bar

för vätskor och gaser

EN-JS1030, 1.0619, 1.4408, 1.4410, CC480K, CC333G

Tryckreducerande ventil T95, för vätskor och gaser

Funktionen hos tryckreducerande ventiler (tryckreglerande ventiler) är att minska ett varierande eller konstant uppströmstryck (inloppstryck) i mediet till ett konstant reducerat tryck (utloppstryck, mottryck) som är beroende av uppströmstrycket.

Tryckreduktionen sker genom att strypa det fria tvärsnittet mellan sätet och konen. Varje tryckförändring på trycksidan nedströms omvandlas omedelbart till en lyftrörelse av ventilkonen.

Ventilen är väl lämpad för intermittent konsumtion. Vid nollförbrukning, det vill säga när förbrukningen på nedströms trycksidan är noll, stängs ventilen säkert genom lågtrycksökning.

Den tryckreducerande ventilen T95 är lämplig för inkompressibla medier, t.ex. tryckluft, naturgas, kväve, samt för inkompressibla medier, t.ex. vatten, olja, bränslen, gasol (propan, butan) etc.

De används främst i industrianläggningar, anläggningsteknik och processteknik.

Tryckreducerande ventiler kan levereras med flänsar eller gängade anslutningar.

DN 15- DN 40 (1/2"- 1 1/2")

PN 16- PN 40

utloppstryck: 0,5–15 bar

för vätskor och gaser

CC480K, CC333G

Tryckreducerande ventil T679 för ånga, vätskor och gaser

Funktionen hos tryckreducerande ventiler (tryckreglerande ventiler) är att minska ett varierande eller konstant uppströmstryck (inloppstryck) i mediet till ett konstant reducerat tryck (utloppstryck, mottryck) som är oberoende av uppströmstrycket.

Tryckminskningen sker genom att strypa det fria tvärsnittet mellan sätet och konen. Via en pulsledning, som redan är installerad på ventilen, trycker det reducerade trycket på en styrkolv. Som ett resultat omvandlas varje tryckförändring på trycksidan nedströms omedelbart till en lyftrörelse av ventilkonen.

Ventilen är väl lämpad för intermittent konsumtion. Vid nollförbrukning, det vill säga när förbrukningen på nedströms trycksidan är noll, stängs ventilen säkert genom lågtrycksökning.

Den tryckreducerande ventilen T679 är lämplig för inkompressibla medier, t.ex. ånga, tryckluft, naturgas, kväve, samt för inkompressibla medier, t.ex. vatten, olja, bränslen, gasol (propan, butan) etc.

De används främst i industrianläggningar, anläggningsteknik och processteknik.

Tryckreducerande ventiler kan levereras med flänsar, svetsändar eller gängade anslutningar.

DN 15- DN 65 (1/2" bis 2 1/2")

PN 16- PN 40

utloppstryck: 0,5–20 bar

med rostfritt stål bälg 1.4571

för vätskor, gaser och ånga

SV-JS1030, 1.0619, 1.7357, 1.4408, 1.4410

Tryckregulator BSi/ BSib, DN15- DN50/ANSI 1/2"- 2"

Fjäderbelastad, automatisk lågtrycksöverströmningsventil i genomgående design för styrning av tryck i mbar området. Tillämpningar är främst integrerat och inert gasöverlagring

Typ: Lågtrycksöverströmningsventil typ BSi / BSib

Byggnation: Passageformulär/In-liner

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 2 bar

Kontrollområde: '-400 mbar till +1200mbarg

Installationslängd: enligt DIN EN558 rad 1,

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Lågtrycksregulatorer BRi/BRib, DN15 – DN50 / ANSI 1/2″ – 2″

Fjäderbelastad, självverkande lågtrycksreducerande regulator (andningsventil, plattventil) i integrerat

design för reglering av tryck i mbar-intervall. Vanlig applicering är insättning och täckning.

Typ: Lågtrycksreducerande ventil typ BRi / BRib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Förtryck: max 8 bar (>8 bar på begäran)

Kontrollområde: '-400 mbar g till +1200mbar g

Installationslängd: enligt DIN EN 558 rad 1, ASME B16.10

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Lågtrycksregulatorer BRi/BRib, DN15 – DN50 / ANSI 1/2″ – 2″

Fjäderbelastad, självverkande lågtrycksreducerande regulator (andningsventil, plattventil) i integrerat

design för reglering av tryck i mbar-intervall. Vanlig applicering är insättning och täckning.

Typ: Lågtrycksreducerande ventil typ BRi / BRib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Förtryck: max 8 bar (>8 bar på begäran)

Kontrollområde: '-400 mbar g till +1200mbar g

Installationslängd: enligt DIN EN 558 rad 1, ASME B16.10

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Tryckregulator BSi/ BSib, DN15- DN50/ANSI 1/2"- 2"

Fjäderbelastad, automatisk lågtrycksöverströmningsventil i genomgående design för styrning av tryck i mbar området. Tillämpningar är främst integrerat och inert gasöverlagring

Typ: Lågtrycksöverströmningsventil typ BSi / BSib

Byggnation: Passageformulär/In-liner

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 2 bar

Kontrollområde: '-400 mbar till +1200mbarg

Installationslängd: enligt DIN EN558 rad 1,

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Lågtrycksregulatorer BRi/BRib, DN15 – DN50 / ANSI 1/2″ – 2″

Fjäderbelastad, självverkande lågtrycksreducerande regulator (andningsventil, plattventil) i integrerat

design för reglering av tryck i mbar-intervall. Vanlig applicering är insättning och täckning.

Typ: Lågtrycksreducerande ventil typ BRi / BRib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Förtryck: max 8 bar (>8 bar på begäran)

Kontrollområde: '-400 mbar g till +1200mbar g

Installationslängd: enligt DIN EN 558 rad 1, ASME B16.10

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Tryckregulator BSi/ BSib, DN15- DN50/ANSI 1/2"- 2"

Fjäderbelastad, automatisk lågtrycksöverströmningsventil i genomgående design för styrning av tryck i mbar området.

Tillämpningar är främst integrerat och inert gasöverlagring

Typ: Lågtrycksöverströmningsventil typ BSi / BSib

Byggnation: Passageformulär/In-liner

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 2 bar

Kontrollområde: '-400 mbar till +1200mbarg

Installationslängd: enligt DIN EN558 rad 1,

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Lågtrycksregulatorer BRi/BRib, DN15 – DN50 / ANSI 1/2″ – 2″

Fjäderbelastad, självverkande lågtrycksreducerande regulator (andningsventil, plattventil) i integrerat

design för reglering av tryck i mbar-intervall. Vanlig applicering är insättning och täckning.

Typ: Lågtrycksreducerande ventil typ BRi / BRib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Förtryck: max 8 bar (>8 bar på begäran)

Kontrollområde: '-400 mbar g till +1200mbar g

Installationslängd: enligt DIN EN 558 rad 1, ASME B16.10

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Tryckregulator BSi/ BSib, DN15- DN50/ANSI 1/2"- 2"

Fjäderbelastad, automatisk lågtrycksöverströmningsventil i genomgående design för styrning av tryck i mbar området.

Tillämpningar är främst integrerat och inert gasöverlagring

Typ: Lågtrycksöverströmningsventil typ BSi / BSib

Byggnation: Passageformulär/In-liner

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 2 bar

Kontrollområde: '-400 mbar till +1200mbarg

Installationslängd: enligt DIN EN558 rad 1,

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Lågtrycksregulatorer BRi/BRib, DN15 – DN50 / ANSI 1/2″ – 2″

Fjäderbelastad, självverkande lågtrycksreducerande regulator (andningsventil, plattventil) i integrerat

design för reglering av tryck i mbar-intervall. Vanlig applicering är insättning och täckning.

Typ: Lågtrycksreducerande ventil typ BRi / BRib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Förtryck: max 8 bar (>8 bar på begäran)

Kontrollområde: '-400 mbar g till +1200mbar g

Installationslängd: enligt DIN EN 558 rad 1, ASME B16.10

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Tryckregulator BSi/ BSib, DN15- DN50/ANSI 1/2"- 2"

Fjäderbelastad, automatisk lågtrycksöverströmningsventil i genomgående design för styrning av tryck i mbar området.

Tillämpningar är främst integrerat och inert gasöverlagring

Typ: Lågtrycksöverströmningsventil typ BSi / BSib

Byggnation: Passageformulär/In-liner

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 2 bar

Kontrollområde: '-400 mbar till +1200mbarg

Installationslängd: enligt DIN EN558 rad 1,

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Lågtrycksregulatorer BRi/BRib, DN15 – DN50 / ANSI 1/2″ – 2″

Fjäderbelastad, självverkande lågtrycksreducerande regulator (andningsventil, plattventil) i integrerat

design för reglering av tryck i mbar-intervall. Vanlig applicering är insättning och täckning.

Typ: Lågtrycksreducerande ventil typ BRi / BRib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Förtryck: max 8 bar (>8 bar på begäran)

Kontrollområde: '-400 mbar g till +1200mbar g

Installationslängd: enligt DIN EN 558 rad 1, ASME B16.10

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Tryckregulator BSi/ BSib, DN15- DN50/ANSI 1/2"- 2"

Fjäderbelastad, automatisk lågtrycksöverströmningsventil i genomgående design för styrning av tryck i mbar området.

Tillämpningar är främst integrerat och inert gasöverlagring

Typ: Lågtrycksöverströmningsventil typ BSi / BSib

Byggnation: Passageformulär/In-liner

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 2 bar

Kontrollområde: '-400 mbar till +1200mbarg

Installationslängd: enligt DIN EN558 rad 1,

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Lågtrycksregulatorer BRi/BRib, DN15 – DN50 / ANSI 1/2″ – 2″

Fjäderbelastad, självverkande lågtrycksreducerande regulator (andningsventil, plattventil) i integrerat

design för reglering av tryck i mbar-intervall. Vanlig applicering är insättning och täckning.

Typ: Lågtrycksreducerande ventil typ BRi / BRib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN50, ANSI 1/2" – 2"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Förtryck: max 8 bar (>8 bar på begäran)

Kontrollområde: '-400 mbar g till +1200mbar g

Installationslängd: enligt DIN EN 558 rad 1, ASME B16.10

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©/PTFE/FPM/EPDM

Anslutningar: Flänsar EN1092-1, formulär B1 PN16 eller ANSI B16.5 cl.150 RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefri och fettfri,

för vätskor, med tryckmätare, andra tätningsremsor

Regulatorer för medelhögt tryck MRC15ib, DN15– 25

Fjäderbelastad, automatisk medeltrycksreducerande ventil i kontinuerlig form för reglering av tryck.

Typ: Medeltrycksreducerande ventil typ MRCib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN25, ANSI 1/2" – 1"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 16 bar

Kontrollområde: 0,5 bar– 15 bar

Installationens längd: Tillverkarens standard

Body material: Stainless Steel 1.4404/1.4409/SS316L, Hastelloy©/2.4602

Membran: Gylon©, PTFE

Anslutningar: Hongänga BSP, NPT-klämma DIN, ISO, ASME, Flänsar EN1092-1 Form B1, ANSI B16.5 klass 150RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefettfri,

för vätskor, definierade ytjämnheten, andra anslutningsformer, med tryckmätare

Regulatorer för medelhögt tryck MRC20ib, DN15– 25

Fjäderbelastad, automatisk medeltrycksreducerande ventil i kontinuerlig form för reglering av tryck. Ren version

Typ: Medeltrycksreducerande ventil typ MRCib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN25, ANSI 1/2" – 1"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 16 bar

Kontrollområde: 0,5 bar– 15 bar

Installationens längd: Tillverkarens standard

Body material: Stainless Steel 1,4404/1,4409/SS316L, Hastelloy©/2,4602

Membran: Gylon©, PTFE

Anslutningar: Hongänga BSP, NPT-klämma DIN, ISO, ASME, Flänsar EN1092-1 Form B1, ANSI B16.5 klass 150RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefettfri,

för vätskor, definierade ytjämnheten, andra anslutningsformer, med tryckmätare

Regulatorer för medelhögt tryck MSC20ib, DN15- 25

Fjäderbelastad, automatisk överströmningsventil med medelhögt tryck i kontinuerlig form för reglering av tryck.

Typ: Medeltrycksreducerande ventil typ MRCib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN25, ANSI 1/2" – 1"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 16 bar

Kontrollområde: 0,5 bar– 15 bar

Installationens längd: Tillverkarens standard

Body material: Stainless Steel 1,4404/1,4409/SS316L, Hastelloy©/2,4602

Membran: Gylon©, PTFE

Anslutningar: Hongänga BSP, NPT-klämma DIN, ISO, ASME, Flänsar EN1092-1 Form B1, ANSI B16.5 klass 150RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefettfri,

för vätskor, definierade ytjämnheten, andra anslutningsformer, med tryckmätare

Regulatorer för medelhögt tryck MRC25ib, DN15– 25

Fjäderbelastad, automatisk medeltrycksreducerande ventil i kontinuerlig form för reglering av tryck. Ren version

Typ: Medeltrycksreducerande ventil typ MRCib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN25, ANSI 1/2" – 1"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 16 bar

Kontrollområde: 0,5 bar– 15 bar

Installationens längd: Tillverkarens standard

Body material: Stainless Steel 1,4404/1,4409/SS316L, Hastelloy©/2,4602

Membran: Gylon©, PTFE

Anslutningar: Hongänga BSP, NPT-klämma DIN, ISO, ASME, Flänsar EN1092-1 Form B1, ANSI B16.5 klass 150RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefettfri,

för vätskor, definierade ytjämnheten, andra anslutningsformer, med tryckmätare

Regulatorer för medelhögt tryck MSC25ib, DN15- 25

Fjäderbelastad, automatisk överströmningsventil med medelhögt tryck i kontinuerlig form för reglering av tryck.

Typ: Medeltrycksreducerande ventil typ MSCib

Byggnation: Passageformulär/In-Line

Storlekar: DN15 – DN25, ANSI 1/2" – 1"

Nominellt tryck: DIN PN10/16, ANSI cl.150

Tryck: max 16 bar

Kontrollområde: 0,5 bar– 15 bar

Installationens längd: Tillverkarens standard

Body material: Stainless Steel 1,4404/1,4409/SS316L, Hastelloy©/2,4602

Membran: Gylon©, PTFE

Anslutningar: Hongänga BSP, NPT-klämma DIN, ISO, ASME, Flänsar EN1092-1 Form B1, ANSI B16.5 klass 150RF

Speciell: Alternativ med pilotventil, som kupoltrycksvariant, oljefettfri,

för vätskor, definierade ytjämnheten, andra anslutningsformer, med tryckmätare

Reducerventiler

DRV 200 / 200 G

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av deras låga friktion av de få rörliga inre delarna.

Normal storlek: DN 8 till DN 50

Inloppstryck upp till 25 bar

Utloppstryck från 0,8 upp till 8 bar

Temperaturområde -15°C till 100°C

DRV 225/226

Tryckreduceringsventiler i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av deras låga friktion av de få rörliga inre delarna.

Normal storlek: DN 8 till DN 50

Inloppstryck upp till 60 bar

Utloppstryck från 1,5 upp till 45 bar

Temperaturområde -15°C till 190°C

DRV 250

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av deras låga friktion av de få rörliga inre delarna.

Normal storlek: DN 8 upp till DN 50

Inloppstryck upp till 25 bar

Utloppstryck från 0,2 upp till 2 bar

Temperaturområde -15°C till 100°C

DRV 230 / 230 G

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av den låga friktionen hos de få rörliga interna delarna.

Normal storlek: DN 8 upp till DN 50

Inloppstryck upp till 25 bar

Utloppstryck från 0,8 upp till 8 bar

Temperaturområde -15°C till 100°C

DRV 235

Tryckreduceringsventiler i serien är kolvmanövrerade, fjäderbelastade tryckreduceringsventiler.

Serien har en hög inställningsnoggrannhet och bra responsbeteende på grund av deras låga friktion av de få rörliga inre delarna.

Normal storlek: DN 8 upp till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 20 bar

Temperaturområde -15°C till 190°C

DRV 302 / 303 / 308

Tryckreduceringsventiler i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har inloppstryckskompensation.

Patrondesignen gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 10 bar

Temperaturområde -30°C till 190°C

DRV 302-6 / 303-6

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronensdesign gör det enkelt att byta ut de inre delarna.

Normal storlek: DN 15 till DN 50,

inloppstryck upp till 16 bar

utloppstryck från 1,5 till 6 bar

temperaturområde -15 °C till 75 °C

DRV 324 / 325

Tryckreducerare i serien är kolvstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronensdesign gör det enkelt att byta ut de inre delarna.

Normal storlek: DN 15 till DN 50,

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 350

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronensdesign gör det enkelt att byta ut de inre delarna.

Normal storlek: DN 15 till DN 50

Inloppstryck upp till 16 bar

Utloppstryck från 0,2 till 2 bar

Temperaturområde -30 °C till 190 °C

DRV 372 / 373 / 378

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronensdesign gör det enkelt att byta ut de inre delarna.

Normal storlek: DN 15 till DN 50,

Inloppstryck upp till 40 bar

Utloppstryck från 0,5 till 9 bar

Temperaturområde -30 °C till 190 °C

DRV 402 / 403 / 408

Tryckreducerare i serien är membranstyrda, fjäderbelastade

Tryckreducerare och har mottryckskompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 till DN 65

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 till 10 bar

Temperaturområde -30 °C till 190 °C

DRV 402-6 / 403-6

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp. Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 till DN 65

Inloppstryck upp till 16 bar

Utloppstryck från 1,5 upp till 6 bar

Temperaturområde -15 °C till 75 °C

DRV 424 / 425

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckkompensation. Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 65

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 450

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 65

Inloppstryck upp till 16 bar

Utloppstryck från 0,2 upp till 2 bar Temperaturområde -30 °C till 190 °C

DRV 472 / 473 / 478

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 65

Inloppstryck upp till 40 bar

Utloppstryck från 0,5 upp till 9 bar

Temperaturområde -30 °C till 190 °C

DRV 502 / 508

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 25 bar

Utloppstryck från 1,5 upp till 10 bar

Temperaturområde -30 °C till 190 °C

DRV 502-6

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 16 bar

Utloppstryck från 1,5 upp till 6 bar

Temperaturområde -15 °C till 100 °C

DRV 524 / 525

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 25 bar

Utloppstryck från 1,5 till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 550

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 16 bar

Utloppstryck från 0,2 upp till 2 bar

Temperaturområde -30 °C till 190 °C

DRV 572 / 578

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 80

Inloppstryck upp till 25 bar

Utloppstryck från 0,5 upp till 9 bar

Temperaturområde -30 °C till 190 °C

DRV 602 / 608

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Alla storlekar kan fås med flänsar enligt DIN, ANSI eller JIS.

Normal storlek DN 65 upp till DN 150

Inloppstryck upp till 16/25 bar

Utloppstryck från 1,5 upp till 10 bar

Temperaturområde -30 °C till 130 °C

DRV 602-6

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Alla tätningar har ELL- och W270-godkännanden, de metalliska komponenterna överensstämmer med UBA:s positivlista.

Normal storlek DN 65 upp till DN 150

Inloppstryck upp till 16 bar

Utloppstryck från 1,5 upp till 6 bar

Temperaturområde -15 °C till 100 °C

DRV 624

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckkompensation.

Alla storlekar kan fås med flänsar enligt DIN, ANSI eller JIS.

Normal storlek DN 65 upp till DN 150

Inloppstryck upp till 25 bar

Utloppstryck från 4 upp till 12 bar

Temperaturområde -15 °C till 100 °C

DRV 672 / 678

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Alla storlekar kan fås med flänsar enligt DIN, ANSI eller JIS.

Normal storlek DN 65 upp till DN 150

Inloppstryck upp till 16/ 25 bar

Utloppstryck från 0,5 till 9 bar

Temperaturområde -30 °C till 130 °C

DRV 702 / 708

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 10 bar

Temperaturområde -30 °C till 190 °C

DRV 703/ 773

Tryckreduceringsventilerna i serien är membranstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 32

Inloppstryck upp till 16 bar

Utloppstryck från 1,5 upp till 6 bar

Temperaturområde -30 °C till 190 °C

DRV 724 / 725

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har tryckkompensation vid inlopp.

Patronens design gör det enkelt att byta ut de inre delarna.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 40 bar

Utloppstryck från 1,5 upp till 20 bar

Temperaturområde -30 °C till 190 °C

DRV 730-D

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckkompensation.

Patronens design gör det enkelt att byta ut de inre delarna. På grund av de tätningsmaterial som används är serien idealisk för ångapplikationer.

Normal storlek DN 15 upp till DN 50

Inloppstryck upp till 16 bar

Utloppstryck från 0,3 upp till 2 bar

Temperaturområde -30 °C till 200 °C

DRV 732-D / 738-D

Tryckreduceringsventilerna i serien är kolvstyrda, fjäderbelastade tryckreduceringsventiler och har en inloppstryckkompensation.