Nivå / Flödestrust.

Nivå / Flödestrust.

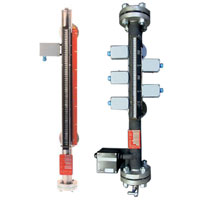

MAGNETICALLY CONTROLLED LIQUID LEVEL INDICATOR ITA – * Indication of the liquid level for corrosive, toxic or flammable media with separation between measurement and display compartments. * Magnetic transmission of the liquid level from the vessel to the gauge is continuous and resistant to vibration. * Can be used to measure level both in atmospheric and pressurized vessels. * Perfect readability of the display elements even at greater distance and after several years, since there is no clouding by product contamination resulting from exposure to ultraviolet light.

FLOW SENSOR IBF-100 – The Itabar flow sensors make it possible to measure the movement of gases, steam and liquids. Special design for stack gas volumetric measurement. The IBF-100 flow sensor was developed especially for stack gas measurements. This flow sensor is engineered to be accessible from both ends so that mechanical cleaning can be undertaken if necessary without having to withdraw the sensor from the sleeve or the stack. This design offers major benefits at pipe diameters of 600 mm (23,62 inch) and more.

CLAMP-ON ULTRASONIC FLOW METERS IS210 – IS210 transit time flow meter utilizes two transducers that function as both ultrasonic transmitters and receivers. The transducers are clamped on the outside of a closed pipe at a specific distance from each other. When the flow meter works, the two transducers transmits and receives ultrasonic signals amplified by multi beam which travels firstly downstream and then upstream. Because ultra sound travels faster downstream than upstream, there will be a difference of time of flight.

DIFFERENTIAL PRESSURE FLOW SENSORS – Once an object is brought into a laminar flowing fluid inside a pipe, the fluid will dam up in front of the object, which generates a raise of pressure. Passing the object the fluid gets accelerated due to the smaller pipe cross section. This acceleration generates a pressure drop on the backside of the object. As all operational conditions at the place of measurement are known, the volume of flow can be calculated by using the difference of the two pressures. D.P. flow elements are Itamar-Flow-Sensors.

DIGIFLOW 505 – Microprocessor Controlled Flow Indicator–Integrator * Full scaleable input signals 4 – 20mA analog or frequency. * 2 Inputs either two independent measuring, Dual range, median of two sensors or 2 different channels. * Integration and indicator of totals when time dependent signals. * Simplified Programming. * User Menus in Three Languages. * Control of a Sensor-purge-unit. * Data Logging Output.

DIGIFLOW 514 – Microprocessor Controlled Flow Indicator–Integrator * Full scalable input signals 4-20m Analog or frequency. * Display of rank total value, preset quantity, flow rate and accumulated quantity. * Two relay outputs for either slow and fast runor two flow channels. * Automatic Overrun compensation. * Alert at signal fault. * Remote Start–Stop. * Simplified programming. * Three languages user interface. * RS 232-protocol interface.

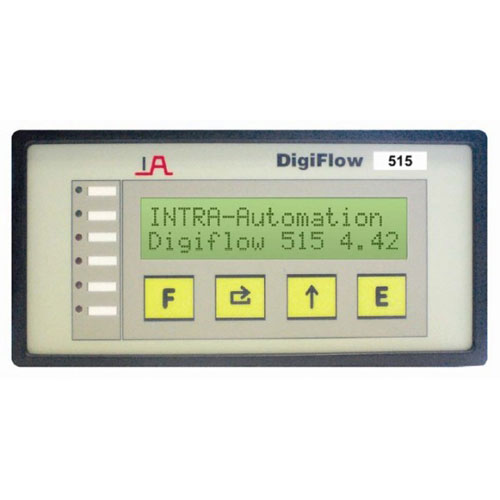

DIGIFLOW 515 – Microprocessor Gas and Steam Flow Computer * Indication of Flow Rate and Total of Volume, Mass and Energy. * Temperature and Pressure Compensation. * Input Signals 4-20 mA analog or frequency for flow input. * Dual Ranged D.P. Transmitter Inputs. * Simplified Programming. * User Menus in Three Languages. * Control of a Sensor-purge-unit. * Data Logging Output.

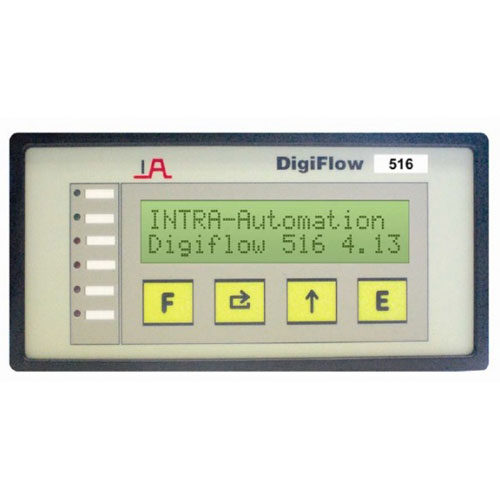

DIGIFLOW 516 – Microprocessor Heat and Energy Flow Computer * Indication of flow rate and total of volume, mass and energy. * Temperature and pressure compensation. * Input signals 4…20 mA analogue or frequency for flow input. * Dual ranged Δp-transmitter inputs. * Simple programming. * User menus in three languages. * Control of a sensor-purge-unit. * Data logging output.

DIGIFLOW 520 – Microprocessor Controlled Digital Level Indicator * Full scaleable input signals 0/4-20m Analog. * Able to process two input signals as two. * Independent measurements. * Simplified programming. * Indication of the tank content in freely definable. * Units. * Barograph. Indicates the current measured. * Percentage. * Correction for non-linear tanks. * Correction for density changes * User menus in three languages. * German – English – French. * RS232-interface or optional RS485-interface

Nivå / Flödestrust.

MAGNETICALLY CONTROLLED LIQUID LEVEL INDICATOR ITA – * Indication of the liquid level for corrosive, toxic or flammable media with separation between measurement and display compartments. * Magnetic transmission of the liquid level from the vessel to the gauge is continuous and resistant to vibration. * Can be used to measure level both in atmospheric and pressurized vessels. * Perfect readability of the display elements even at greater distance and after several years, since there is

Read More

FLOW SENSOR IBF-100 – The Itabar flow sensors make it possible to measure the movement of gases, steam and liquids. Special design for stack gas volumetric measurement. The IBF-100 flow sensor was developed especially for stack gas measurements. This flow sensor is engineered to be accessible from both ends so that mechanical cleaning can be undertaken if necessary without having to withdraw the sensor from the sleeve or the stack. This design offers major benefits at pipe diamet

Read More

CLAMP-ON ULTRASONIC FLOW METERS IS210 – IS210 transit time flow meter utilizes two transducers that function as both ultrasonic transmitters and receivers. The transducers are clamped on the outside of a closed pipe at a specific distance from each other. When the flow meter works, the two transducers transmits and receives ultrasonic signals amplified by multi beam which travels firstly downstream and then upstream. Because ultra sound travels faster downstream than upstream, there wi

Read More

DIFFERENTIAL PRESSURE FLOW SENSORS – Once an object is brought into a laminar flowing fluid inside a pipe, the fluid will dam up in front of the object, which generates a raise of pressure. Passing the object the fluid gets accelerated due to the smaller pipe cross section. This acceleration generates a pressure drop on the backside of the object. As all operational conditions at the place of measurement are known, the volume of flow can be calculated by using the difference of the two

Read More

DIGIFLOW 505 – Microprocessor Controlled Flow Indicator–Integrator * Full scaleable input signals 4 – 20mA analog or frequency. * 2 Inputs either two independent measuring, Dual range, median of two sensors or 2 different channels. * Integration and indicator of totals when time dependent signals. * Simplified Programming. * User Menus in Three Languages. * Control of a Sensor-purge-unit. * Data Logging Output.

DIGIFLOW 514 – Microprocessor Controlled Flow Indicator–Integrator * Full scalable input signals 4-20m Analog or frequency. * Display of rank total value, preset quantity, flow rate and accumulated quantity. * Two relay outputs for either slow and fast runor two flow channels. * Automatic Overrun compensation. * Alert at signal fault. * Remote Start–Stop. * Simplified programming. * Three languages user interface. * RS 232-protocol interface.

DIGIFLOW 515 – Microprocessor Gas and Steam Flow Computer * Indication of Flow Rate and Total of Volume, Mass and Energy. * Temperature and Pressure Compensation. * Input Signals 4-20 mA analog or frequency for flow input. * Dual Ranged D.P. Transmitter Inputs. * Simplified Programming. * User Menus in Three Languages. * Control of a Sensor-purge-unit. * Data Logging Output.

DIGIFLOW 516 – Microprocessor Heat and Energy Flow Computer * Indication of flow rate and total of volume, mass and energy. * Temperature and pressure compensation. * Input signals 4…20 mA analogue or frequency for flow input. * Dual ranged Δp-transmitter inputs. * Simple programming. * User menus in three languages. * Control of a sensor-purge-unit. * Data logging output.

DIGIFLOW 520 – Microprocessor Controlled Digital Level Indicator * Full scaleable input signals 0/4-20m Analog. * Able to process two input signals as two. * Independent measurements. * Simplified programming. * Indication of the tank content in freely definable. * Units. * Barograph. Indicates the current measured. * Percentage. * Correction for non-linear tanks. * Correction for density changes * User menus in three languages. * German – English – French. * RS232-interface or optional

Read More