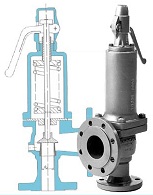

SAFETY VALVE SPRING LOADED HIGH-EFFICIENCY DIAPHRAGM TYPE – Safety valve to satisfy safety requirements in heating systems with flow temperatures of 120°C according to DIN 4751 Pt. 2. Spring loaded, diaphragm type, high-efficiency safety valve, angled, with highly elastic seal and metal backing in the valve head. Series 341 with closed bonnet Valve head is liftable. The pressure acts, via a ball, centrally onto the valve head. Corrosion-resistant spindle bushes ensure reliable and precise response of the valve.

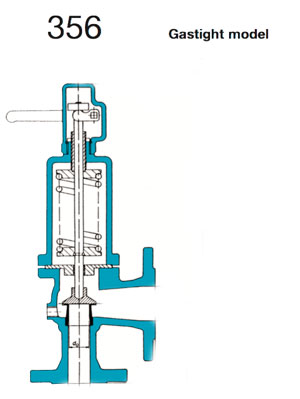

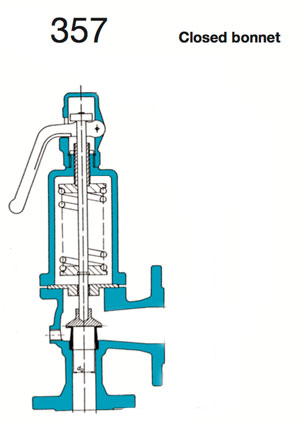

SAFETY VALVES – SPRING LOADED HIGH-EFFICIENCY – Application: As safety valves for steam, gases and hot water in pressure vessels and steam boilers. Series 357 version with closed bonnet Liftable valve head. Force is transmitted centrally at the valve head via ball. Corrosion-resistant spindle guides ensure reliable and precise response of the valve.

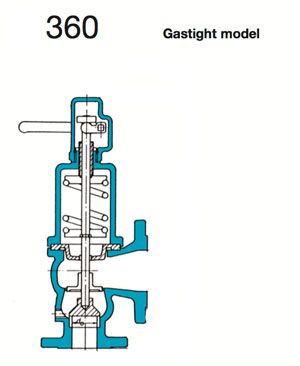

SAFETY VALVES – SPRING LOADED HIGH-EFFICIENCY – Series 360, Gas-tight with closed protective bonnet and closed lift housing. Safety valves for blowing-off liquid from fixed pressure vessels, subject to the condition that no evaporation occurs. Also suited to district heating systems. If the liquid to be blown off does not have similar properties to the liquid (water) used in the valve testing procedure, then the properties of the liquid, in respect to chemical aggressiveness or sticking tendency, must be taken into account in the acceptance testing of the pressure vessel.

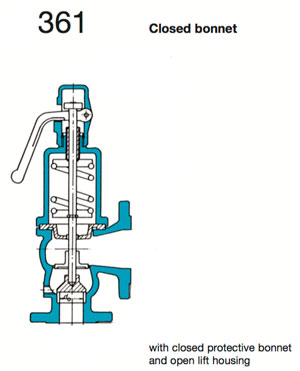

SAFETY VALVES – SPRING LOADED HIGH-EFFICIENCY – Series 361 with closed protective bonnet and open lift housing. Valve head is liftable. Force is transmitted centrally at the valve head. Corrosion-resistant spindle guides ensure reliable and precise response of the valve. Safety valves for blowing-off liquid from fixed pressure vessels, subject to the condition that no evaporation occurs. Also suited to district heating systems.

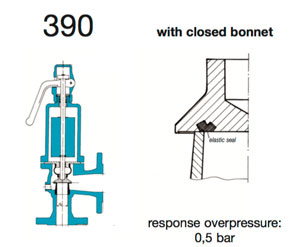

SAFETY VALVES – DIAPHRAGM HIGH-EFFICIENCY – 390 with closed bonnet, response overpressure: 0,5 bar. Nom. diam. 25 to 100. Liftable valve head. Force is transmitted centrally at the valve head via ball. Corrosion-resistant spindle guides ensure reliable and precise response of valve. These safety valves are for blowing-off saturated steam from pressure generators.

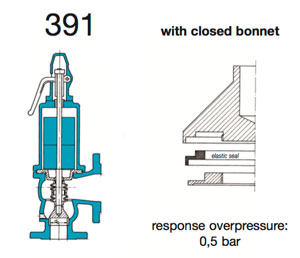

SAFETY VALVES – DIAPHRAGM HIGH-EFFICIENCY – 391 with closed bonnet, response overpressure: 0,5 bar, nom. diam. 125 to 150. Weight loaded, diaphragm type, high-efficiency safety valve, angled, with highly elastic seal and metal backing in valve head. Liftable valve head. Force is transmitted centrally at the valve head via ball. Corrosion-resistant spindle guides ensure reliable and precise response of valve. These safety valves are for blowing-off saturated steam from pressure generators.

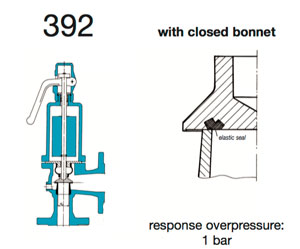

SAFETY VALVES – DIAPHRAGM HIGH-EFFICIENCY – 392 with closed bonnet, response overpressure: 1 bar, nom. diam. 25 to 50. Weight loaded, diaphragm type, high-efficiency safety valve, angled, with highly elastic seal and metal backing in valve head. Liftable valve head. Force is transmitted centrally at the valve head via ball. Corrosion-resistant spindle guides ensure reliable and precise response of valve. These safety valves are for blowing-off saturated steam from pressure generators.

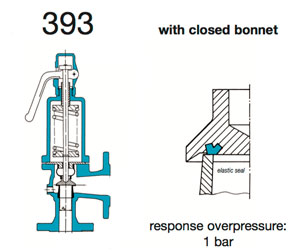

SAFETY VALVES – DIAPHRAGM HIGH-EFFICIENCY – 393 with closed bonnet, response overpressure: 1 bar, nom. diam. 25 to 100, nom. diam. 125 to 150. Spring loaded, diaphragm type, high-efficiency safety valve, angled, with highly elastic seal and metal backing in valve head. Liftable valve head. Force is transmitted centrally at the valve head via ball. Corrosion-resistant spindle guides ensure reliable and precise response of valve.

SAFETY VALVE WITH SPRING LOADING MODEL 095 – The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase. Design in accordance with “International Standard ISO 4126-1:2004 Safety Valves”. In accordance with the requirements of directive 97/23/EC. EC valve verification certified by: TÜV Internacional Grupo TÜV Rheinland, S.L. EC 0035.

SAFETY VALVE WITH SPRING LOADING MODEL 096 – The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase. Design in accordance with “International Standard ISO 4126-1:2004 Safety Valves”. In accordance with the requirements of directive 97/23/EC. EC valve verification certified by: TÜV Internacional Grupo TÜV Rheinland, S.L. EC 0035.