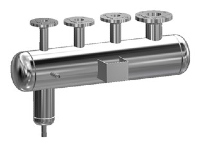

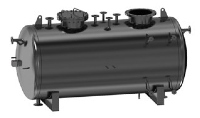

FA21.1

The FA21.1 is a range of fully automatic ball float traps specially designed for condensate drainage in compressed air and gas systems. Typical applications include aftercoolers, separators and compressed air mains.

MATERIAL: SG iron

SIZES: 1/2” to 1” – DN 15 to DN 25

CONNECTIONS:

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1/-2 PN 16

Flanged ASME B16.42/B16.5 Class 150

MAX. OPERATING PRESSURE: 14 bar

MAX. OPERATING TEMPERATURE: 198 ºC