Model G-GM

Materials Graphite

Dimensions DN 25 – DN 600

Rupture pressure 0.017 – 15 bar g (depending on diameter)

Tolerance from +/- 10 % to +/- 20%

Operating temperature from -60 °C to 180 °C

Operating margin up to 75%

Vacuum support Available

Fragmentation Yes

Use under valve No

Corrosion resistance Very good – can be protected with a PTFE membrane

Linings No

Container Included, mounted between flanges

Seals Available in graphite

Rupture sensor Electrical

PED Certification [CE STAMP] Available

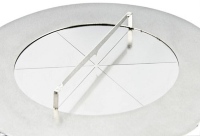

GRAPHITE DISCS, G-GA

Model G-GA

Materials Graphite and Stainless steel

Dimensions DN 25 – DN 300

Rupture pressure 0.017 – 15 bar g (depending on diameter)

Tolerance from +/- 10 % to +/- 20%

Operating temperature from -60 °C to 300 °C

Operating margin up to 75%

Vacuum support Not Available

Fragmentation Yes

Use under valve No

Corrosion resistance Very good – can be protected with a PTFE membrane

Linings No

Container Included, mounted between flanges

Seals Available in graphite

Rupture sensor Electrical

PED Certification [CE STAMP] Available

DOUBLE WAY LPD

Model LPD

Materials Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium

Membrane PTFE, PFA

Dimensions DN 2\”(50) – DN 20”(500)

Rupture pressure 5 – 500 millibar g (depending on material and diameter)

Tolerance from +/- 5 % to +/- 20%

Operating temperature up to 265 °C

Operating margin up to 60%

Vacuum support Available

Fragmentation No (membrane only)

Use under valve Yes

Corrosion resistance Good – can be protected with a PTFE membrane

Linings Yes

Container Mounted between flanges

Rupture sensor Electrical, Magnetic, Inductive, Optical

ATEX EX II 2 GD Certification Available

DOUBLE WAY DIF

Model DIF

Materials Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium

Membrane PTFE, PFA, Stainless steel, Aluminium

Dimensions DN 2”(15) – DN 40”(1000)

Rupture pressure 0.5 – 5 bar g (depending on material and diameter)

Tolerance from +/- 5 % to +/- 20%

Operating temperature membrane in PTFE/PFA max 265°C, up to 480°C (depending on the membrane)

Operating margin up to 70%

Vacuum support Available

Fragmentation No (membrane only)

Use under valve Yes

Corrosion resistance Good – can be protected with a PTFE membrane

Linings Yes

Container Mounted between flanges

Rupture sensor Electrical, Magnetic, Inductive, Optical

PED Certification [CE STAMP] Available

ATEX EX II 2 GD Certification Available

ULTRA LOW PRESSURE LPD

Model LPD

Materials Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium

Membrane PTFE, PFA

Dimensions DN 2\”(50) – DN 20”(500)

Rupture pressure 5 – 500 millibar g (depending on material and diameter)

Tolerance from +/- 5 % to +/- 20%

Operating temperature up to 265 °C

Operating margin up to 60%

Vacuum support Available

Fragmentation No (membrane only)

Use under valve Yes

Corrosion resistance Good – can be protected with a PTFE membrane

Linings Yes

Container Mounted between flanges

Rupture sensor Electrical, Magnetic, Inductive, Optical

ATEX EX II 2 GD Certification Available

ULTRA LOW PRESSURE DIF

Model DIF

Materials Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium

Membrane PTFE, PFA, Stainless steel, Aluminium

Dimensions DN 2”(15) – DN 40”(1000)

Rupture pressure 0.5 – 5 bar g (depending on material and diameter)

Tolerance from +/- 5 % to +/- 20%

Operating temperature membrane in PTFE/PFA max 265°C, up to 480°C (depending on the membrane)

Operating margin up to 70%

Vacuum support Available

Fragmentation No (membrane only)

Use under valve Yes

Corrosion resistance Good – can be protected with a PTFE membrane

Linings Yes

Container Mounted between flanges

Rupture sensor Electrical, Magnetic, Inductive, Optical

PED Certification [CE STAMP] Available

ATEX EX II 2 GD Certification Available

REVERSE ACTING Y90

Model Y90

Materials Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium

Dimensions DN 1”(25) – DN 8”(200)

Rupture pressure 0.2 – 70 bar g (depending on material and diameter)

Tolerance from +/- 5 % to +/- 20%

Operating temperature From – 196°C up to 600°C

Operating margin 90% – Able to reach 95% depending on the conditions of service

Fragmentation No

Use under valve Yes

Corrosion resistance Very good

Linings Yes

Container HR/A, HR/P, HR/F, HTC

Rupture sensor Electrical, Magnetic, Inductive, Optical

PED Certification [CE STAMP] Available

ATEX EX II 2 GD Certification Available

REVERSE ACTING SCR

Model SCR

Materials Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium

Dimensions DN 1”(25) – DN 36”(900)

Rupture pressure 0,41 bar g (6 psi g)- 137 bar g (2000 psi g) (depending on material and diameter)

KRg 0.48

Tolerance from +/- 5 % to +/- 20%

Operating temperature From – 196°C up to 480°C

Operating margin 90% – Able to reach 95% depending on the conditions of service

Fragmentation No

Use under valve Yes

Corrosion resistance Very good

Linings Yes

Container HR/A, HR/P, HR/F, HTC

Rupture sensor Electrical, Magnetic, Inductive, Optical

ASME Certification [UD STAMP] Available

PED Certification [CE STAMP] Available

ATEX EX II 2 GD Certification Available

REVERSE ACTING KRD

Model KRD

Materials Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium

Dimensions DN 1”(25) – DN 36”(900)

Rupture pressure 0,41 bar g (6 psi g)- 137 bar g (2000 psi g) (depending on material and diameter)

Kr l 0.48

Tolerance from +/- 5 % to +/- 20%

Operating temperature From – 196°C up to 480°C

Operating margin 90% – Able to reach 95% depending on the conditions of service

Fragmentation No

Use under valve Yes

Corrosion resistance Very good

Linings Yes

Container HR/A, HR/P, HR/F, HTC

Rupture sensor Electrical, Magnetic, Inductive, Optical

ASME Certification [UD STAMP] Available

PED Certification [CE STAMP] Available

ATEX EX II 2 GD Certification Available

FORWARD ACTING STD

Model STD

Materials Stainless steel, Alloy 201, Alloy 400, Alloy 600, Alloy 625, Alloy C276, Titanium

Dimensions DN ½”(15) – DN 24”(600)

Rupture pressure 5 – 1150 bar g (depending on diameter)

Tolerance from +/- 5 % to +/- 20%

Operating temperature up to 600 °C

Operating margin up to 70%

Fragmentation Yes

Use under valve No

Corrosion resistance Very good

Linings Yes

Container SU/M, SU/T, HI/A, HI/P, HI/F

PED Certification [CE STAMP] Available