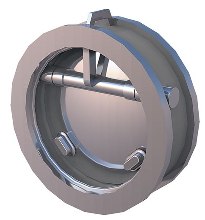

Spjällbackventil 2646-2646F

Backventilen har snedställd klaff och säte. Detta ger korta stängningstider.

Klaffen är upphängd mellan två axeltappar. Ventilen har tät svetsade axlar som

eliminerar risken för medialäckage till omgivningen. Ventilen är metalliskt tätande.

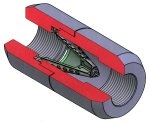

I ventiler med fjäderbelastad klaff (2646F, endast fr.om. DN80) stänger ventilen

innan media strömmen vänder. Detta minskar risken för tryckslag.

Tekniska data

Flödesriktning: Enkelriktad

Material: Rostfritt stål

Material: Syrafast stål 316 (1.4408)

Temperatur (C°): -40 – +400

Tryckklass (PN): 10 – 63

Anslutning: Flänsad EN1092

Montageposition: Vertikal, Horisontell

Montageposition notering: Vertikalt montage endast möjligt vid stigande flöde.

ETIM klassning: EC010596 – Backventil för inspänning