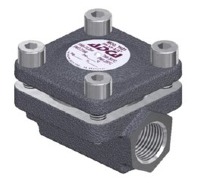

TH32i

MATERIAL: Stainless steel

SIZES: 1/2” to 1” ; DN 15 to DN 25

CONNECTIONS:

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 150 or 300

Socket weld (SW) ASME 16.11

MAX. OPERATING PRESSURE:22 bar

MAX. OPERATING TEMPERATURE: 250 ºC

FLOW RATE CAPACITY: Up to 795 kg/h